ООО "АТ-GAZ

About us

- Since 2009, AT-Gaz LLC has been developing and improving in order to provide its customers with equipment and services of the highest quality.

- AT-Gaz LLC develops design documentation for industrial facilities of any complexity, and also supplies high-tech equipment.

Due to extensive production capabilities and solid experience of implementation of projects of different complexity AT-Gaz LLC realizes projects in the shortest possible time with minimum risks for the customer and offers cost-effective solutions.

AT-Gaz LLC takes part in major projects in Russia and CIS.

The priority of the company is individual approach, high quality of work performed and compliance with deadlines.

The AT-Gaz LLC unites a group of qualified, creative and responsible people whose goal is the integrated supply of complete solutions for industrial construction projects, private housing construction, as well as special-purpose facilities and urban infrastructure.

AT-Gaz LLC is the official partner of the International concern DoorHan.

Products designed for any working conditions

When creating products, all possible conditions for their further operation, including a wide range of ambient temperatures, different climatic zones and voltage fluctuations, are taken into account.

Wide range of equipment from one manufacturer

Rich production and technological experience, versatility and comprehensive approach allow our company to offer our customers a wide range of equipment required to equip any facility.

High level of service

- Accurate selection of equipment.

- Departure of experts directly to the site for measurement.

- The work of qualified installation teams.

Optimum ratio «Price-quality»

Our own production of components, the presence of 24 production and storage complexes and the developed logistics allow us to offer products optimal in terms of «price - quality».

Minimum delivery times

A wide network of sales offices allows you to purchase ready-made sets of products, components and spare parts of products on the same day.

Maintenance in all regions

A wide network of service centers provides professional warranty and post-warranty service for products in the regions.

Modular buildings and other structures

Shift residential complexes

Shift residential complexes

Administrative and domestic complexes

Administrative and domestic complexes

Logistics centres

Logistics centres

Storage buildings and structures

Storage buildings and structures

Vapor recovery units

Oil Product/LPG loading/unloading plants

AUTOMATED WAREHOUSE COMPLEXES

All stages of the design

- Audit of the existing warehouse system, description of technological and business processes.

- Development of advanced technological and business processes.

- Calculation of storage area parameters.

- Development of advanced organizational structure of the warehouse.

Supply of equipment

- Design, manufacture and supply of automated storage systems.

- Selection of personnel identification equipment.

- Selection and calculation of the of the quantity of intralogistic tools.

- Full range of installation and commissioning works.

Implementation

- Staff consultation.

- Maintenance of trial operation of the warehouse complex.

- Adaptation of user documentation based on the results of the pilot operation.

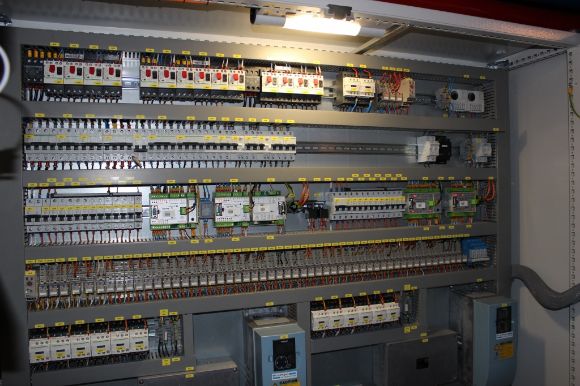

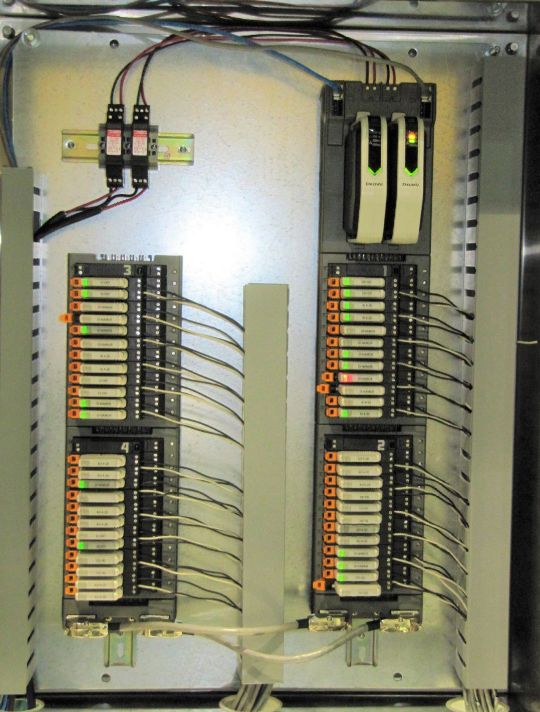

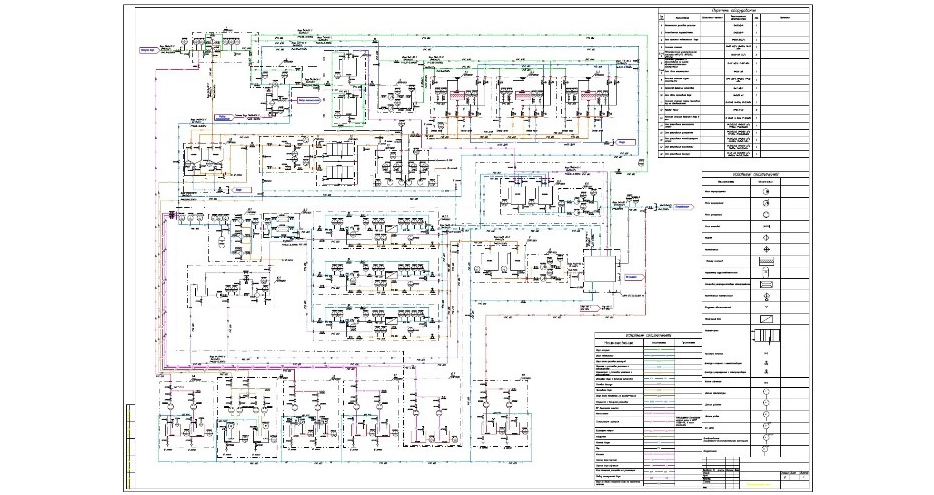

APCS

Activity of the company

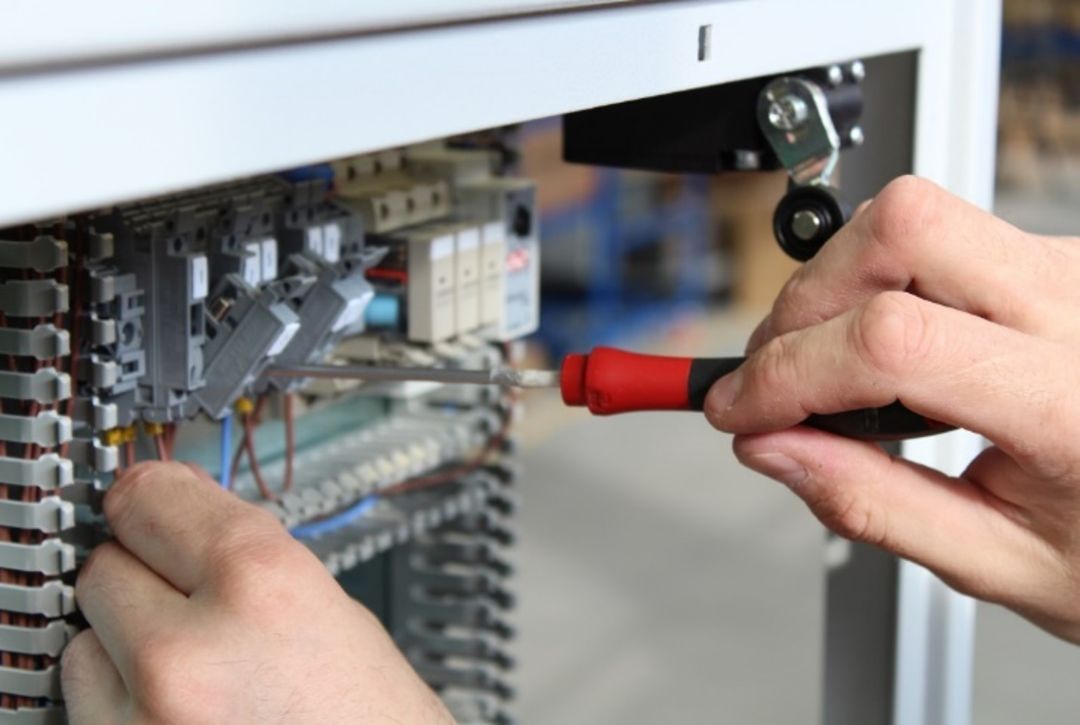

AT-Gaz LLC also specializes in the development and production of import-substituting programmable logic controllers (PLC) and other automation equipment, design and turnkey supply of process control systems based on them for various industries, as well as the development of application software.

Pre-project works on creation of ACS TP

AT-Gaz LLC offers services to Customers on inspection of objects of automation and on performance of complex of pre-project works at registration of technical task.

Design of APCS

Designing is the most complex, responsible and requiring highly qualified performers stage of creating an automation system.

Experience

AT-Gaz LLC employs engineers with extensive experience in designing and reengineering APCS systems.

Documentation

At this stage, the customer receives complete project documentation: terms of reference, draft design, technical design and working documentation.

Quality

High quality and speed of project implementation are achieved through the use of automated design systems (CAD) Compass-3D and E3.series.

Standards

Compliance of the working documentation and design solutions with the current Russian standards (GOST) and safety rules is confirmed by the conclusions of the industrial expertise on the completed projects.

Development, production and supply of technical means

AT-Gaz LLC, together with partners, develops and serially produces microprocessor controllers of various information capacities, which allow solving a full range of automation tasks - from systems with a small number of signals to automatic process control systems for power units, the number of input-output channels of which is in the thousands.

- Warranty and post-warranty service, technical support.

- Modernization and maintenance of existing APCS systems.

AT-Gaz LLC also performs service of systems of third-party developers:

- Regular inspections and maintenance.

- Urgent departures in case of failures and accidents.

- Prompt delivery of spare parts and accessories (PTA), incl. from own warehouse.

- Comprehensive system diagnostics.

- Software debugging and upgrading.

- Storage of software and documentation backups.

- Testing and repair of equipment.

- Systems assessment and risk analysis.

- Compilation of spare parts regulations and specifications.

ООО "АТ-GAZ"

Application

Power plants

Pulp and paper mills

Petrochemical production

Concentrating and metallurgical enterprises

Food industry

WATER CONDITIONING AND WATER TREATMENT:

The implementation of individual technological solutions for each Customer allows to increase the efficiency of equipment, reduce operating costs, increase the service life of equipment, reduce the concentration and volume of effluents at reconstructed facilities; as well as to put into operation modern, efficient, optimal in terms of price-quality ratio systems at facilities under construction.

The high quality of work is ensured by qualified specialists with extensive experience in the industry, systematic quality control of design products and technical control at production. Quality control of the services and equipment provided is ensured by the Certificate of Conformity of the Quality Management System to the national standard GOST R ISO 9001-2008.

© 2023 All rights reserved.